DIYers new to manufactured products may wonder how to cut composite decking once they start planning their build. Cutting lumber and composite boards follow nearly identical processes — with a few particular best practices to note.

This guide covers everything you need to know about cutting composite decking so everyone from experienced craftspeople to DIY homeowners can confidently prepare and install their manufactured boards. Be sure to also review manufacturer-specific guidelines before you begin.

In This Article:

- Installation do’s and don’ts

- Tools

- Prepare your workspace

- Square cut ends

- Measure your boards

- Cut to size

- Install and clean up

TimberTech Tip:

Ensure the deck substructure is properly framed with joists in plane and blocked together before cutting deck boards. Follow manufacturer guidelines for joist spacing recommendations.

Do’s and don’ts for cutting composite decking

Cutting composite decking requires power tools, so safety is a top priority. There are also some best practices to provide the best results for your deck that may vary from wood decks, so check out all of our do’s and don’ts below before you cut your composite boards.

Safety 101

- Do wear personal protective equipment (PPE) including eye and ear protection when using power equipment

- Do keep hands at a safe distance from saw blades and follow manufacturer instructions and warnings

- Do use proper equipment and sharp, quality blades

- Unplug saws when they aren’t in use

- Don’t wear loose and baggy clothing when operating power equipment

- Do ensure all cutting equipment is in good shape with proper guards and safeties

Cutting and installation best practices

- Do install quickly after cutting to minimize board length changes due to expansion or contraction

- Do store composite boards flat and out of direct sunlight

- Do keep boards cool as possible during cutting and fastening

- Don’t sand composite decking

Composite deck cutting tools

Composite boards are cut with the same saws you’d use for lumber, and all saws used should be in good working condition with proper safety implements in place. We recommend a power miter saw to cut TimberTech boards, but each saw has its own benefits and addresses different needs:

| Saw type | Best for | Blade recommendation |

|---|---|---|

| Miter | Cutting boards to length, square, and angle cuts | Fine-tooth, carbide-tipped trim blade |

| Circular | Rip cutting boards to width, cutting boards to length with use of a guide | Fine-tooth carbide-tipped finish blade |

| Table | Rip cutting boards | Fine-tooth carbide-tipped finish blade |

| Jigsaw | Cutting around obstructions and posts | Fine-tooth finish blade |

Make sure you follow proper safety precautions, including wearing personal protective equipment, while operating power tools.

1. Prepare your workspace

Proper preparation and equipment will help you cut your deck boards safely and maintain clean cuts while you do it. First, always store composite decking out of direct sunlight and flat, and install deck boards quickly after cutting to minimize expansion and contraction caused by temperature changes.

There are a few items you’ll need before you get started, including:

- Miter saw (or other saw)

- Proper saw quide

- Fine-toothed, carbide-tipped saw blade

- Saw horses

- Personal protective equipment

- Speed square

- Straight edge

- Tape measure

- Carpenter’s pencil

Once you have everything you need to measure and cut your boards, as well as all safety equipment, you’re ready to start cutting.

2. Square cut board ends

Your first cut is trimming the factory end of your deck board. Then, measure twice and use a speed square and pencil to mark the proper length. Use a saw to cut the deck board to the desired length.

3. Measure and mark your boards

Once the factory ends are squared, measure and mark your deck boards to their appropriate length. Measure from the square cut to the length you need and mark the board with pencil. Measure twice before cutting to avoid any mistakes.

4. Cut to size

When your cut is marked, align the mark on your board with your saw blade. Miter saws are ideal. Cut one board at a time with the surface or textured-side up. Actually cutting the composite deck board should be similar to cutting other types of lumber.

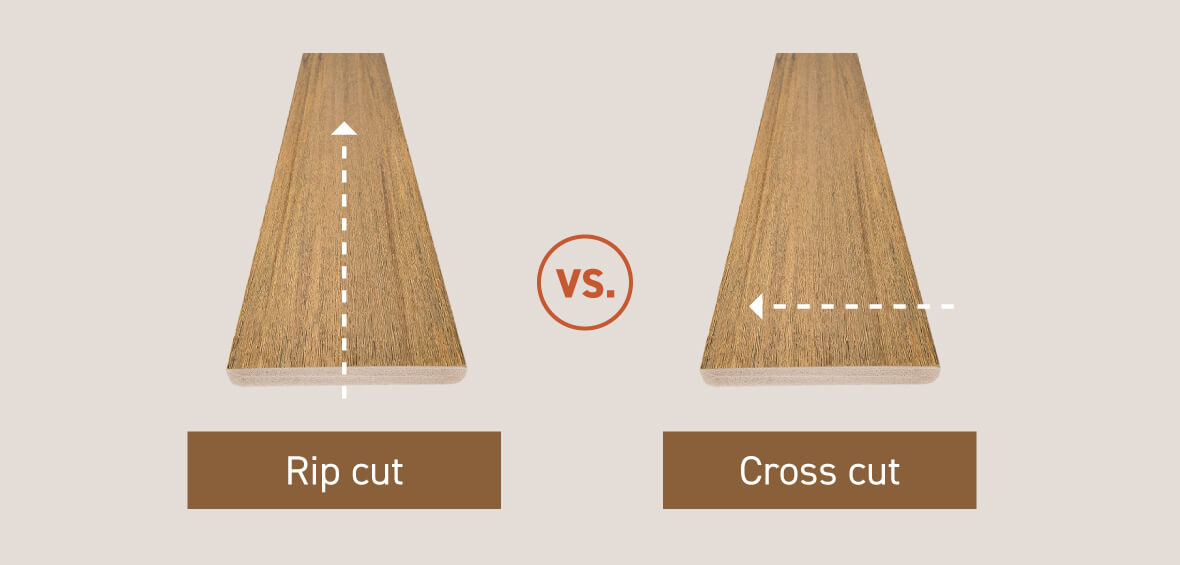

Most of your boards just need a cross cut to length, but you’ll likely need to reduce the width of some boards toward the end of your project. These are called rip cuts in composite and wood decking.

Rip cut vs. cross cut

A rip cut reduces the width of a board with a cut all the way up its length. Rip cutting helps you build any deck size without worrying about whether the boards will fit within your substructure.

For a well-polished deck surface, you would plan and construct the deck’s size to eliminate the need for a rip cut board, as rip cuts are unsightly. However, you may need to rip cut a board if your deck shape or size doesn’t perfectly accommodate a full-width final deck board. There are special considerations including additional framing and fastening techniques, so double-check that your substructure can support rip-cut boards.

Rip cutting is relatively easy, but there are some extra safety and installation tips to know. A table saw is ideal for consistent cuts, but you can also use a circular saw with a proper blade and guide.

It’s also a good idea to use a push stick or scrap wood to push the boards through the table saw. This allows you to control a short piece of wood while protecting your hands.

In either case, we recommend boards stay at least ⅓ of their original width for best performance.

5. Install and clean up

Cut and install boards one at a time to minimize length changes due to temperature exposure.

Once everything’s installed, use manufacturer cleaning instructions and wipe away any dust and debris to protect the boards and prevent discoloration. You can enjoy your new composite deck once you finish cleaning — no need for sealer like with wood decks.

FAQ

Will cutting composite decking void my warranty?

No, composite decking boards are designed to be cut for a number of deck designs and sizes. Both rip and cross cuts are appropriate for composite decking and won’t void your warranty.

Do I need a special blade to cut composite decking?

You don’t need any special blades to cut composite decking, but using proper sharp blades provides the best results. Generally, we recommend sharp, fine-finish, carbide-tipped blades with high tooth counts, depending on the saw type and blade size.

Should I sand my composite decking?

No. Most modern composite boards feature a protective polymer cap to protect the board from moisture, UV exposure, and other damage. Sanding your composite boards would damage the protective capping, potentially voiding your warranty and impacting the look and performance of your composite deck.

For the most part, how you cut composite decking is similar to how you cut lumber and wood decking. The cutting process is very similar, but there are some board storage and installation best practices for composite decking that support a polished finished project.

DIYing a deck isn’t easy, but there are a number of lifestyle and equity benefits to a beautiful new deck. If you’re ready to extend your outdoor living space but want to skip cutting decking, contact a qualified contractor to build your deck without worry.